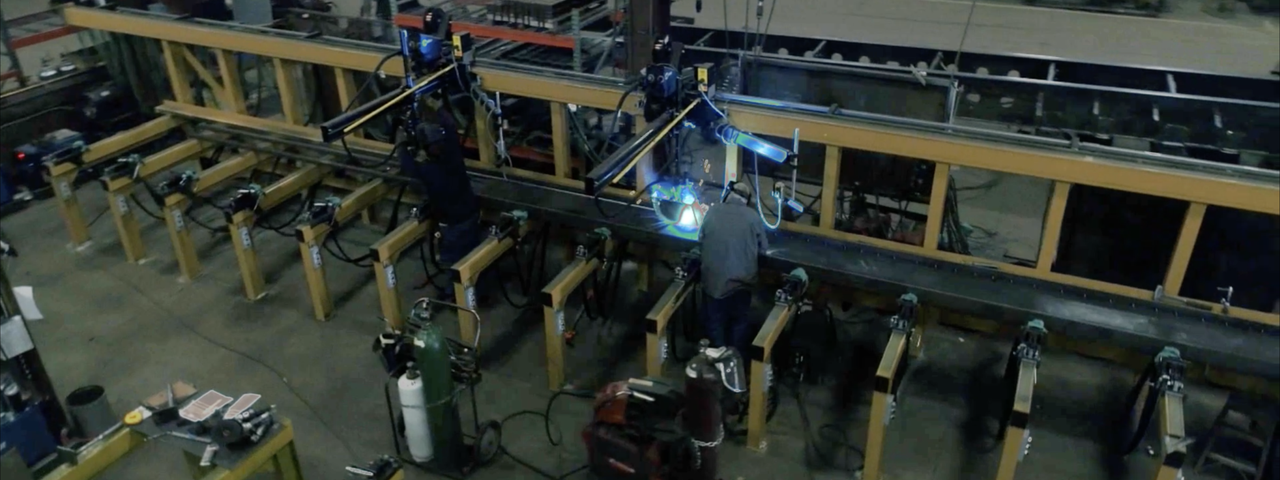

SmithCo recently installed a pair of custom frame rail welding tables. Each table is 64 feet long and 7 feet wide, and enables the SmithCo team to weld both the top and bottom flange in a single, continuous weld pass. The result: the straightest, most consistent side dump trailer frame beams SmithCo has ever produced.

“The three main objectives of this project were to improve weld quality, increase manufacturing efficiency, and improve worker safety,” said Scott Lovell, SmithCo President and CEO, “By reducing the number of times we have to move or handle our large frame rails, we greatly improved both worker safety and efficiency. For the customer, they are getting a more consistent and more professionally welded frame rail.”

Read more about the rail table design and implementation here.